Subhi.in’s Iron Wrokers Machine: Making Construction Processes Better.

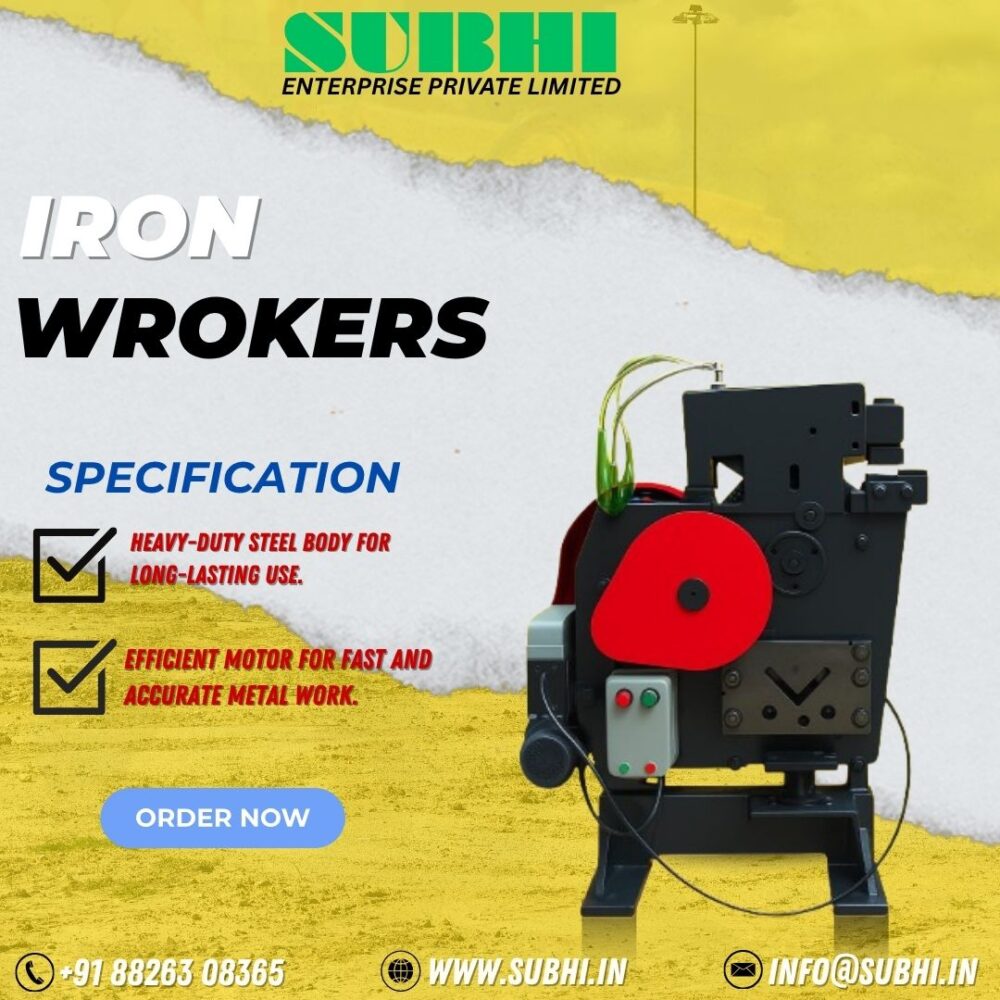

Every construction project has to meet basic safety and quality standards, but the industry wants them done faster and faster. Iron Wrokers Machines build metal structures for construction. These machines are very flexible and can do a lot of different things, which is why they are so popular on construction sites, in fabrication shops, and in manufacturing units. Subhi.in has Iron Wroker Machines for these reasons.

Machines for Iron Wrokers:-

Iron Wroker Machines can do a lot of different things with sheet and rod metals. They include punching, shearing, notching, and bending. Before, making metal workpieces required separate machines for each step, which took up space and time. Iron Wroker Machines combine several machines into one, which makes the industry more efficient and productive.

Iron Wroker Machines also have the benefit of being able to automate frames and gates with built-in control systems.

In addition to doing a lot of other work, these machines also help builders work faster on the many different types and levels of precision metal components and frameworks.

What an Iron Wroker Machine Can Do:-

Iron Wroker Machines are very safe, easy to use, and functional, and they work well and reliably.

First, an Iron Wroker has some unique features:

- Design Efficiency: One of the benefits of all the operations being performed by a single device is the simplification of operations, reduction of costs, and control of clutter.

- Sound Construction: Strapping steel while building machines is enclosed and protected to keep them safe while construction progresses.

- High-Precision Tools: Modern construction tools like CNC and mechanical punch systems make sure that even the simplest tasks, like cutting, bending, and punching holes in sheets and bars of metal, are done with precision.

- Customized Operation: Each machine’s adjustable operational configuration offers a unique way for the user to define a specific set of specifications for a particular task.

- Safety: Advanced Workers use emergency overrides, safety shields, and systems to control overload to stop accidents from happening.

- Streamlined Maintenance: Getting a machine up and running doesn’t require time-consuming tasks, and operational tasks that stay set even after a machine reset can keep running.

- Optimised Power Usage: The newest machines use the least amount of power.

Iron wrokers learn how to keep things safe at construction sites. This is very clear in the Subhi.it Specification Guide for Iron wroker machines.

- Subhi.in Iron Wroker machines focus on reliable, adaptable, and well-built iron wroker machines for construction. These are what the specifications say.

- Every machine has power settings that range from 5 to 10 horsepower, so there is a wide range of power levels.

- All of the machines can shear, punch, and notch 12, 25, and 10 mm sheets of mild steel, and they can also bend 12 mm sheets.

- Depending on the model, the machines weigh between 1200 and 1800 kg, have work tables that are 800 x 600 mm, and run on 220V 3 phase and 380V supplied voltages.

- All of the frameworks for safety precaution machines have emergency stop buttons, fully enclosed guards, and mechanisms to protect against overload.

- There is no doubt that the machines can do the jobs they are supposed to do quickly and well.

- The wide range of safety features is fully explained by how flexible and adaptable the machines are.

In the formal operational context of the metal industry, possible application situations are unimaginably broad.

- Lessening the amount of work: Heavy lifting and other hard tasks like punching, cutting, and bending iron sheets can cause serious injuries and make wrokers tired. Iron Wrokers have to lift heavy things and do other hard and tiring work, which can lead to injuries and fatigue.

- Consistent Work Product Flow: Work flow that doesn’t stop depends on finishing some manual tasks. The main reasons for disruptions are the workers’ different levels of skill and fatigue. Specially designed Iron Wrokers machines address these gaps as they perform tasks with operational perfection, thus improving the quality of the final product.

- Comprehensive Automation: Automating some tasks gets rid of the risks and injuries that operators were exposed to. Automating bending and cutting tasks in the work cells also cuts down on the amount of manual work needed and greatly lowers the risk of injuries from these tasks.

- Task Simplification: The biomechanical phenomenon of a single worker performing multiple tasks on one machine without additional tools helps to diminish task sequenced steps. This phenomenon makes a job much easier, which cuts down on waste in the work area.

What Iron Worker Machines Do:-

- Worker machines for iron construction do a lot of different things in all kinds of businesses, such as:

- Construction: Worker machines at construction sites do all the cutting, punching, and bending of iron that is used in beams, frames, and scaffolds.

- Fabrication: This is the process of making framed structured parts, as well as gates, brackets, and fences.

- Industrial manufacturing: Different types of machines are used to make parts, support structures, sheets of metal, and other machines used in production.

- On-Site Maintenance: This is fixing and changing metal parts.

An iron construction worker helps businesses streamline their processes and get better results for their operations.

Why is Subhi.in the Best for Iron Wroker Machines?

- According to Subhi.in, the first thing any business should do to add value is buy iron worker machines. This is why Subhi.in makes the best iron worker machines in its field:

- Built with Care: Subhi.in machines show that the builders pay attention to the small things, build things consistently, and are committed to making something.

- Value for All Business Sizes: No matter how big or small your business is, you can get value at a fair price without having to give up quality.

- A consultative approach:We offer client consultations for custom designs, one-on-one service, and tool upkeep.

- Flexibility of the machine:We change the machines’ power and settings to fit the needs of your business.

- Performance that is reliable and of high quality:High-quality replacement parts make sure that the machine works well and is reliable.

Safe Ways to Use Iron Wroker Machines:-

- Iron Wroker Machines have a lot of safety features, but Operators still need to pay close attention. Please take note of the following:

- You must always wear full protective gear, like gloves, shoes, and eye protection.

- You can’t take off safety guards or leave machines running without anyone watching them.

- Before you use the machine, make sure it is on level, stable ground.

- When it comes to keeping the workplace clean, trash and clutter must be thrown away, and the work area must be neat.

- Make sure that each machine in your operation is serviced properly and on a regular basis.

Final Thoughts:-

The Iron Wroker Machine can do many things, is very strong, and makes work safer, more productive, and better quality, all while keeping users safe. It shows that iron worker machines are now widely used in the building and fabrication industries.

Our machines are safe, which makes metal construction and fabrication more efficient and fits right into the way work is done. This shows how serious the company is about safety, accuracy, and getting things done.

Our iron wroker machines will greatly improve the quality, accuracy, strength, and productivity of your metal construction and fabrication work.