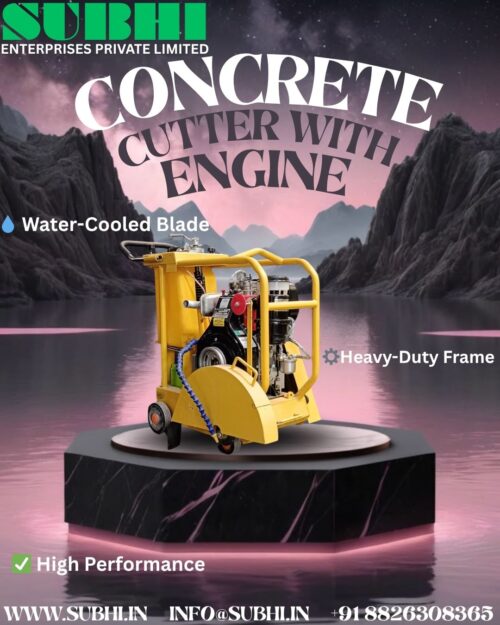

Concrete Cutter with Engine: The Definitive Guidebook to Cutting-Edge Building Construction Sites

https://subhi.in/contact-us/Accuracy and performance are the benchmarks of the modern building age. Whether constructing a skyscraper, rehabilitating highways, or cutting through reinforced concrete, there is just one machine that excels in performance and dependability—the Engine Concrete Cutter. The machine has transformed the way contractors, engineers, and builders tackle concrete cutting jobs, providing power, accuracy, and mobility to every construction site.

In this complete guide, we’re going to talk about all there is to an engine concrete cutter—from its mechanism and components to its benefits and application, and how employing Subhi Enterprises’ model can be a strong contributor in your next project.

What is an concrete cutter with engine?

An concrete cutter with engine is a heavy machine used to cut concrete, asphalt, and other hard building materials. In contrast to electric or hand cutters, the machine employs a heavy petrol or diesel engine to produce heavy torque and sustained performance even where there is no electricity supply.

The main use of an engine concrete cutter is to create straight, clean cuts in concrete slabs, pavement, or flooring for repairs, expansion joint repairs, and demo locations. It’s a highly valuable piece of equipment in the toolbox of road maintenance crews and construction personnel.

How an Concrete Cutter With Engine Operates?

The engine side of the concrete cutter operates on a very straightforward but highly efficient mechanism:

- Power Source of Engine: The blade shaft is driven by the petrol or diesel engine.

- Rotation of Blade: A diamond-coated circular cutting blade is driven by motor power.

- Penetration of Blade: As the operator pushes the cutter forward, the rotating blade penetrates through the surface of the concrete.

- System of Water Supply: There is a built-in water reservoir that regularly sprays water in a continuous stream over the blade to cool and avoid dust.

- Smooth Cutting: The outcome is a smooth, clean, and precise cut with minimal surface damage.

Main Parts of a Concrete Cutter with an Engine

An engine-powered concrete cutter is meant to be efficient and durable. The key parts that render it efficient and durable are explained below:

- Engine: The hub of the machine—petrol or diesel-powered, with lots of torque and an extended lifespan.

- Cutting Blade: Usually a hardened steel or diamond-edged blade able to slice through reinforced concrete.

- Handle & Frame: Ergonomically designed for convenient handling and agility.

- Tank for Water: Minimizes overheating of the blade and also minimizes dust emission when cutting.

- Depth Control System: Enables control of the depth of cut as per specifications by the user.

- Wheels & Bearings: Enable smooth mobility and stability on all kinds of surfaces.

Advantages of an Concrete Cutter With Engine

Subhi Enterprises’ Engine Concrete Cutter boasts the most modern technology, which makes it one of the most durable tools to be found:

- Strong Engine: Delivers reliable cutting power in extreme conditions.

- Precision Depth Control: Provides depth control adjustment to meet any project demand.

- Heavy-Duty Blade: Slices through rebar, concrete, asphalt, and pavement with ease.

- Water Cooling System: Prevents blade overheating, prolongs its lifespan, and minimizes dust.

- Ergonomic Design: Balanced weight and comfortable-to-grip handles to provide maximum control.

- Vibration-Free Operation: With anti-vibration components for safe handling.

- High Durability: Made of heavy-duty steel frames that are resistant to extreme site conditions.

- Low Maintenance: Washable, cleanable, and serviceable for long-lasting use

Uses of Concrete Cutter with Engine

The concrete cutter engine is a versatile tool that can be used in multiple industries and applications:

- Road Repair & Construction: To cut expansion joints, asphalt, and road surface adjustment.

- Construction Works: To provide for precise floor and slab cutting in new or renovation construction work.

- Bridge & Dam Construction: Employed to slice heavy concrete structures efficiently and securely.

- Utility Building: Assisted in slicing trenches and slicing the surface to install cables or pipes.

- Airport Pavements & Runways: Perfect for expanding joint slicing or sealing out that is in need of repair.

- Demolition Work: For accurate concrete slicing before removing or building.

Benefits of an Engine Concrete Cutter

The engine concrete cutter possesses a number of advantages that immediately benefit project cost, schedule, and quality. Here’s why professional builders make it their first option:

1. Portability and Independence

Since a diesel or petrol engine powers it, the Engine Concrete Cutter is not electricity reliant. It can thus be utilized at will in rural and outdoor environments.

2. Unbelievable Resilience

The power frame by the engine provides greater cutting torque and a good source of power, so deep cut sizes and heavy-duty applications are made possible.

3. Precise Cutting

The latest technology blades make smooth and straight cuts with less chipping or damage to other surfaces.

4. Time-Saving Effort

Hand cutting is tedious and uneven work. The Concrete Cutter with Engine mechanizes the task, saving time and effort.

5. Achieved Safety

Having water cooling and dust management systems provides a safer working environment through the elimination of airborne dust and overheat of blades.

6. Cost-Effective Solution

Though the initial cost is expensive, due to its long lifespan, low maintenance cost, and high efficiency, it is extremely cost-effective in the long term.

Models of Concrete Cutter with Engine

Based on your project requirements and work requirements, there are different models of engine-driven concrete cutters available:

- Diesel Concrete Cutter with Engine—Most appropriate for heavy-duty industries with high torque and extended work hours.

- Petrol Concrete Cutter with Engine—Most ideal for mini- to medium-sized jobs with quick starting and agility.

- Engineer Walk-Behind Concrete Cutter—most suited for easy control on pavements, roads, and slabs.

- Hand-Held Concrete Cutter with Engine—mini-engineered and most appropriate for mini repair work and small areas.

- Every engine-type concrete cutter is designed for particular site conditions and provides flexibility in various building contexts.

Choosing the Most Suitable

Engine-Powered Concrete Cutter

Your job’s ideal engine-powered concrete cutter will govern its prodSelecting the Most Appropriate Engine-Powered Concrete Cutter.

Your work’s best engine-powered concrete cutter will determine its productivity and finish quality. Take into consideration:

Engine Type: Choose petrol or diesel based on fuel availability and project size.

- Cutting Depth: Leave sufficient clearance space for the cutter so that your deepest desired cutting depth can fit.

- Blade Compatibility: Choose machines that are compatible with generic diamond-tipped blades.

- Water System: Choose models with an on-board water tank to decrease dust.

- Build Quality: Make sure the machine casing is corrosion-resistant and durable.

- Mobility: Choose models with heavy-duty wheels to facilitate easy transferability of sites.

- Brand Reliability: Select such brands as Subhi Enterprises that offer guaranteed performance and service backup.

Maintenance Tips for Concrete Cutter with Engine

To have the best performance and longest life from your engine concrete cutter, use the following professional maintenance tips:

- Now and then, inspect and replace the air filter.

- Replace engine oil after every 50 working hours.

- Inspect and tighten all nuts and bolts before operation.

- Keep the blade well-sharpened and clean for precise cutting.

- Ensure the water system is clear and in working condition.

- Keep the machine dry and under a cover to prevent corrosion.

- Timely maintenance not only makes it safe for use but also makes it last longer.

Why Subhi Enterprises' Concrete Cutter with Engine?

Performance, post-sales support, and reliability are areas where Subhi Enterprises shines through as one of India’s leading construction equipment suppliers. Subhi Enterprises Engine-Powered Concrete Cutter items are crafted with the vision of providing rock-solid performance in the worst possible situation.

That is why professionals prefer us:

- Heavy-Duty Construction: Constructed with heavy-duty components for long-lasting reliability.

- New Engine Technology: Fuel-saving engines for greater power output.

- Effective Water Cooling System: Keeps blades cool and dust levels under control.

- Tailored Solutions: Free in various capacities and models.

- Post-Sales Support: Personalized service and availability of genuine spare parts.

- Trusted by the Professionals: Suggested for use by well-known builders, contractors, and government schemes across India.

- You’re getting what you pay for in terms of quality, performance, and peace of mind with the Subhi Enterprises Concrete Cutter with Engine.

- Environmental & Safety Benefits ,

Conclusion

Not only is an engine-driven concrete cutter a building tool—it’s a must-have for today’s building projects that demand accuracy, strength, and quickness. Whether building a highway or a bridge, an airport or a building, this heavy-duty engine-driven concrete cutter ensures every cut to be precise, clean, and efficient.