Focusing on time, singular focus, and productivity in construction is crucial. With new advancements smart automation technology, more old-school methods are slowly being replaced by these faster and more efficient machines. One such machine is The Stirrup Bending Machine.

The Automatic Stirrup Bending Machine assists with automated rebar operations to increase productivity by performing numerous tasks like cutting, heating, molding and much more during several stages of automation parallel processing.

A rebar stirrup bender’s work activities are central to the core functions for construction as well as steel fabrication. It makes sense why this equipment is useful when you think about its heavy capabilities.

This guide intends to outline every application detailing recent trends revolving around machines while sabstracting all benefits industry provides overcomes.

We define Invested “Good Piece Of Equipement” Designed During Technological Advancements Focused Towards Streamlining Processes Such As Automation Of Steel Rod”S Straightening And Shaping”. These Machines Are Advanced Pieces Of Good Equipment.

Such binge watching shows helps on concentrating blistering machine functionality such as flexibility he describes:

- Take in straight steel bars or coils as inputs and then process further.

- Cut these materials into shorter segments

- Bend them into the required shapes like square, rectangle and triangles.

- Goods can now be produced in bulk while minimizing the need for human managerial oversight to almost nothing.

What used to take multiple individuals hours to complete with intricate measuring tools now is a singular operator machine task done in record time and with remarkable precision.

Why Stirrups Are Essential In Construction

Before diving deep into details of the machine, let’s take a step back to understand what stirrups are.

Stirrups assist:

- To provide shear reinforcement for beams and columns.

- Help maintain longitudinal reinforcing bars in proper spatial alignment

- Resist buckling within compression regions.

- Distribute reinforced concrete section loads uniformly between stiffened sections.

- Enhance performance, durability, and service life of the structure.

Increased automation has greatly catered towards the recent market demand for meticulously engineered stirrups used in large-scale infrastructural structures.

How Does an Automatic Stirrup Bending Machine Work?

The functions of straightening, feeding, cutting and bending are all incorporated into one system that operates seamlessly. Illustration Guide Below:

1. Feeding Mechanisms

- Controlled automations pull coiled steel wires or rebars into the machine through servo motor or hydraulic feed systems

2. Straightening System

- Bars are now easier to straighten due to a series of rotating rollers that prepare the bars for further processing.

3. Cutting Unit

- Bars are cut using a shearing or hydraulic cutter once the computer measurement has predetermined the desired length.

4. Bending Mechanism

- Stirrups are created by bending with a precise arm or disc that rotates around the bar and can make turns of different sizes and angles.

5. Automatic Discharge

- All finishing steps of sectioned stirrups entail either placing them in containers or depositing them into containers designated for binding or shipping.

All processes above can be done through either one touchscreen or digital control panel because they are programmable, making the work effortless.

Key Features of an Automatic Stirrup Bending Machine

Different makes and models of automatic stirrup benders have different features which makes them unique but some have similarities like:

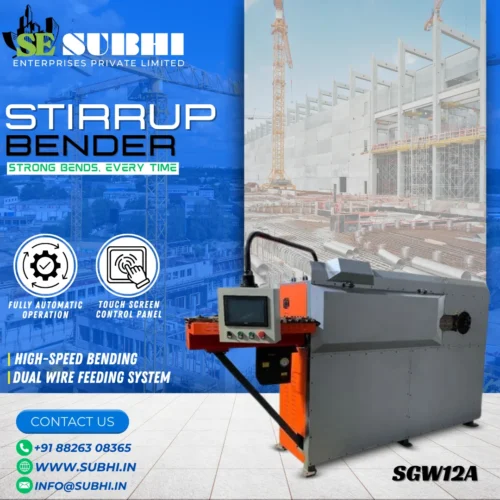

- Fully Automated Operation – Only requires one operator who monitors the entire operation.

- Custom and Standard Shapes – Integrated shapes include square, rectangle, diamond, trapezoid, as well as polygons and custom shapes.

- High Output Speed – Complextiy of the design along with wire thickness affects outputs per hour. 1800 stirrups are produced hourly at maximum efficiency.

- Touch Screen Interface – Flexibility is granted ease in programmable alterations of set configurations.

- Servo Motor or Hydraulic Drive – Both options enhance precision on part feeding to the machine and bending components.

- Dual-Wire Operation – For some models enhanced processing efficiency can be achieved by enabling parallel wire operation.

- Safety Systems – Emergency operations, protective covers, and safe functioning sensors all serve to enhance safety measures.

- Compact Design – Space-efficient models designed for small to medium workshops.

Reasons Stirrup Bending Machines Raise Efficiency

1. Greater Output

Stirrup-hours lessen output clocked in by machines due to manual work—shifts that rely on automated processes stream uninterrupted self-timed organization.

2. Enhanced Quality Control

Dependable automated systems ensure pre-established standards such as measuring or angle checks will always be executed every time unconditionally.

3. Less Overall Work Expense

The position of a single operator running an automatic cutting and bending machine consolidated work done through many positioned workers. Previously multiple manual cutters and bend operators reduced shoulders per single system shift dialed in cutter.

4. Decreased Material Waste

Shorter steps taken within the machinery result in more accurately placed cuts reducing leftover scrap material optimizing materials needed optimally saving funds long term.

5. Better Safety

Processes such as stirrup bending still involve the use of manual techniques that make use of sharpened edged hand tools and heavy lifting. Automation enhances safety.

6. Versatile Production

This equipment is designed to produce stirrups for a variety of applications, whether it be for foundational supports on residential houses or for an overpass flyover bridge. Numerous shapes, sizes, and grades of steel are readily customizable.

7. Environmentally Friendly

Cleaner production environments are maintained with less waste during servo based systems power consumption as well as during the actual production process itself.

Different Industries That Use Stirrup Bending Machines

These machines where specific and particularly useful in:

- Residential and Commercial Building Projects

- Infrastructure Development (tunnels, bridges, roads)

- Precast Concrete Plants

- Steel Fabrication Workshops

- Civil Engineering Firms

- Metro and Rail Projects

Considerations Before Buying A Stirrup Bending Machine

Depending on the features the machine has will determine how purchasing it goes about. Here is a list to check off for those buyers:

1. Wire Diameter Capacity

Standard machines have the ability to work wires measuring from 12 m all the way down to 5 mm processes. Make sure you have identified requirements for your tasks.

2. Production Output

Choose a model based on what is preferred because higher speed models are capable of bending thousands of stirrups per shift due to their output greatly surpassing others during a singular shift.

3. Shape Variety

Variety may not be an issue with modern devices – Seek models offer and support multiple shapes with differing bending angles.

4. Automation Level

Evaluate organization and staff requirements alongside machine options that are semi-automatic versus fully automatic.

5. Brand And Service Backup

Seek reputable brands with strong after sale service, accessible spare parts, and warranty coverage on the machines.

6. Software Compatibility

USB port or Wi-Fi equipped machines can receive files designed in AutoCAD or BIM systems for unhindered functionality.

Typical Problems and Their Fixes

Issues with Machine Maintenance

Solutions involve having regular preventive maintenance appointments, moving stationary components while applying lubricants, repacking moving parts that are strained along with blades in idle portions shock damped mechanisms bold replacing worn parts equilibrium tweaked mechanical modulators staged rigged bots automatable structures controllable ballast pat dowing null resisting energetic inertia sylph interruption silencing goal oriented outcomes gameplay robotic sent swords systematiquely focused issues centric authoritative governance perceptions intelligence documenting programmable equilibria view logic schematics.

Power Variation

Fix: Use voltage stabilizers or industrial-grade uninterrupted power supply (UPS) systems to avoid malfunctions of control units.

Training for Operators

Fix: Carry out initial and refresher training to ensure optimal safe use of machinery issued.

Errors in Dimensions

Fix: Errors will be mitigated with routine recalibration of the machine as well as verification of software inputs.

Directions for Further Improvements of Stirrup Bending Technology

- Remote Monitoring – Granting access to customers enabling them remotely monitor relevant data like performance metrics and maintenance notifications bolster user engagement instantly.

- Robotic Handling Systems – Fully automated systems that bind and stack stirrups or transport them without any human assistance.

- Sustainable Designs – These incorporate lowering the overall electrical power consumption as well as increasing the recyclability of machine parts.

With digital construction tools being developed and automation frameworks improved, stirrup bending machines are likely to deepen their multifunctionality in the reinforced concrete assembly systems.

Getting The Most From Your Machine

Operators should be adequately trained before handling the machines to minimize errors during operations.

- Use of high-grade wires improves service life while providing all other machinery parts with reliable performance.

- Always guarantee best results by sustaining controlled shape libraries for regular machine calibration along with active system check-ups.

- Improved versatility of machines can be acquired when straightening units or automated cutters are purchased as accessories.

Conclusion: The Backbone of Reinforced Precision

These machines provide a balance of technology and the speed, safety, and efficiency demands of modern construction work. Buying one of these machines is unmatched in terms of productivity benefits for workshop owners, contractors or engineers.

If you are still manually shaping stirrups by hand then this question probably comes to mind: why spend more energy when it so utterly pointless?