In conversations surrounding advanced construction machines for concrete floor finishing, ‘Trimix machine—safari’ has gained traction with contractors, builders, and site supervisors. This gives rise to several questions. What does this entail? Why has the Trimix machine – safari gained so much attention in project meetings and procurement lists? And how can builders or contractors determine if a Trimix machine-safari would be worth your investment? Let us analyze this in detail.

What is "Trimix machine – safari"?

At first, the phrase “Trimix machine—safari” might not make any sense. Let’s examine the components.

Trimix machine: In construction usage, and quite different from diving-gas usage, a Trimix machine is a piece of equipment used to finish and process concrete slabs. It combines three functions, thus the “tri” in trimix, such as mixing, placing, and finishing concrete or smoothing and leveling floors. In India, manufacturers describe their “Trimix flooring machine” or “Trimix machine” as a semi-automatic machine that helps in concrete finishing. (jcmcindia.com)

Safari: Here, this refers to the brand name SAFARI (more fully, Safari Construction Equipments Pvt. Ltd.), which is a well-known Indian manufacturer of construction machines. Various equipment is displayed on their webpage, including elements of the “TREMIX System” (which could be a different spelling or variant), such as vacuum pumps, vibrating screeds, etc. (safariequipments.co.in)

Consequently, “Trimix machine—safari” refers to the Trimix machine made by Safari Construction Equipments, designed for concrete flooring, finishing, dewatering, or leveling.

Why the Label Matters

For builders, the phrase is shorthand. “Trimix machine—safari” means “the Safari brand’s Trimix/finishing machine.” When you say “Trimix machine – safari,” you’re indicating you want a reliable brand that provides after-sales service, spare parts, and a design suited to Indian sites.

Why contractors are choosing a Trimix Machine - Safari

1. Efficiency & Productivity Gains

Among the many factors to consider for the Trimix Machine – Safari, the productivity gains it offers for large floor slabs are one of the best. When it comes to manual finishing, it takes much longer, it comes with much variability with labor, and it is more difficult to standardize the process. Owning a Trimix Safari Machine offers you:

- Higher rate of finishing and smoothing of surfaces

- More uniform quality across the entire slab

- Less labor is required for repairs.

2. Finish Quality

Concrete flooring requires good finishing, and the Trimix machine – safari makes achieving this much more attainable since it has the brand’s “TREMIX System” category that includes walking-behind or ride-on smoothing machines, vacuum pumps for de-watering slabs, and vibrating screeds for leveling. Safari’s emphasis on quality construction indicates that the Trimix machine – safari is designed to withstand the rough treatment on-site. (safariequipments.co.in)

3. Challenges of the Indian Worksite and Indian Servicing

Many imported machines often miss the mark due to local site challenges like excessive dust, unstable power supply, variability with operators, and availability of spare parts. Servicing a Trimix machine safari offers the local servicing advantage. Parts will be more accessible, engineers will understand the local context, and support will be more responsive. Safari brand’s motto is “Built on Trust, Powered by Innovation.” (safariequipments.co.in)

4. Project Versatility

The Trimix machine – safari has models and configurations that are designed for a variety of scales to fit the needs of your workload, whether you are doing large-scale constructions like high-rise floor slabs and industrial warehouse floors or smaller residential buildings.

Standardizing finishing tools for each project enables improved asset utilization.

Key features in a Trimix machine – safari

When considering a Trimix machine – safari for purchasing—these features are worthwhile:

1. Walk-behind machines versus ride-on machines: A walk-behind Trimix machine—safari—is adequate for medium/slab-sized jobs; however, for large slabs, a ride-on machine is more efficient due to faster coverage.

- Width and diameter of the finishing heads: The finishing head/blade size is directly proportional to the area that is covered in one pass.

- Power source: Electric, petrol, and diesel options are available. This selection should match the site’s controlled noise level and power availability.

2. The number of blades, along with the thickness and diameter of the finishing head, determine the efficiency and surface finish. A “Trimix flooring machine” in a different brand used 4 blades on a 3 mm thickness (jcmcindia.com).

3. Adjustable handles or finishing angles allow for more precise adjustments needed for different slabs.

4. The chassis and drive system are essential for reducing downtime due to rough site conditions. Trimix machine – safari has to endure rough site conditions for the chassis and drive to be reliable. Look for rugged quality builds and impressive drive systems.

5. Site Adaptability

Power flexibility includes assessing if it can take three-phase input, fluctuating voltages, etc.

- The need for portability: can it be easily transported and maneuvered between jobs?

- Parts availability: for a Trimix machine – safari, check whether Safari offers spare blades, handles, and motor parts.

- Manufacturer support: Does Safari give training, manuals, and commissioning aid?

6. Value-added features

The vacuum dewatering includes finishing.

- Screed leveling attachments: In Safari’s portfolio under “TREMIX System,” vibrating screeds are listed. (safariequipments.co.in)

- Maintenance-friendly design: easy access to lubricants, blades, and service points.

Use-cases and advantages on-site with a Trimix machine—safari

1. Residential high-rise floor slabs

For a 30-story residential building, finishing the slab for the 10th and 30th floors becomes a repetitive task. A Trimix machine—safari will:

- Reduce finishing time by 30-40%

- Ensure flatness consistency across floors.

- Reduce re-work and patching.

2. Industrial warehouse with a large floor area

In a warehouse with 10,000 m² of floor, the need for fast finishing is critical to meet tight timelines. With a ride-on Trimix machine—safari—one operator can manage large spans quickly. The smooth finish also matters for forklift operations, etc.

3. Specialized Floors (RCC Roads, De-watering Duties)

Safari Integrates vacuum pumps into flooring/finishing tasks within the “TREMIX System.” (safariequipments.co.in) This indicates that the trimix safari ecosystem can accommodate specialized flooring types (e.g., heavy-duty slabs, RCC roads) where water removal or air entrapment is essential.

Tips on Buying and Procurement for Your Business

Since you’re in a business-to-customer model (like you do through your company), ROI is impacted significantly by your selection and procurement strategy.

Align Your Specifications to the Project Portfolio

If most of your project pipeline is residential mid-rise, you probably do not need to acquire the largest trimix machine – safari model. Select a model that is aligned to your average slab area, finishing level, and the skill level of the operator.

Total cost of ownership (TCO)

Look beyond the acquisition cost:

- Operating cost (fuel/electricity)

- Maintenance (spares, blades)

- Downtime cost (machine unavailable mid-project) vv

Supplier relationship & support

You understand the value of machinery choice in relation to client satisfaction. Equipment choice affects client satisfaction in the long run. For Safari:

- Warranty terms

- Service network (Delhi/NCR or your regions)

- Availability of certified operators/trainers

- The Trimix machine—safari provides on-site demonstrations

- Marketing benefit & client pitch

Equipped with high-end machines like the Trimix machine – safari, you can confidently promote: “We utilize advanced finishing equipment to achieve remarkable flatness and durability.” You can attract builders focused on quality floors by emphasizing the machine brand on Instagram and LinkedIn.

Maintenance & best practices for optimal performance

After you have acquired a Trimix Safari machine, make sure that you take proper care of it to ensure maximum value for your investment.

Daily check of blades/finishing heads: ensure they’re sharp and have no wear & tear.

After every use, the machine must be cleaned to remove any residue of concrete that promotes corrosion.

Do check the lubrication of the drive system and look for irregular vibrations.

Operators must be trained sufficiently. The operator’s smoothness in handling the machine directly correlates to the quality of the finish and the amount of rework required.

Use only genuine Safari spares. Blade quality and drive parts varying from Safari’s may compromise the finish.

Record hours of production and downtime in a log. This way, you will be able to schedule preventive maintenance and achieve maximum ROI in the shortest time.

Common myth-busting about the Trimix machine

Myth 1: It’s only for large projects.

Reality: While large slabs benefit the most, a proper model of the Trimix machine can be used in medium-sized projects too, and often smaller slabs as well. The time and labor cost savings can be significant.

Myth 2: Manual finishing is cheaper.

Manual finishing may lead to more patching, uneven surfaces, and delayed handover, so in the long run, it is more expensive. The Trimix machine pays back in reduced reworks and improved quality.

Myth 3: Imported machines are always better.

While marketed imported machines may have better features, their after-sales support, parts, and adaptation to Indian job sites may cost you more. The Trimix machine offers a locally designed solution with service benefits.

How to integrate the Trimix machine - safari into your workflow

Step 1: Pre-planning

Plan for the arrival of equipment, assignment of operators, and site logistics before slab pours. Specify the Trimix machine – safari will be used for finishing.

Step 2: Concrete pouring & initial screeding

After concreting and initial finishing, the Trimix machine – safari is used for final finishing. The operation should be done at the correct speed along the specified path.

Step 3: Floating/finishing phase

Depending on the finish needed, operate the machine controls to run and finish the surface. Adjust settings (rpm, blade angle) to the condition of the slab.

Step 4: Quality Check and Curing

Once you are done with the Trimix machine—safari, cure the slab properly. Ensure the flatness and smoothness parameters are met. For advertising purposes, you can say, “finished with the Trimix machine—safari for a superior finish.”

Step 5: Log and Review

Make sure to record the slab finishing time, finishing quality, and the machine hours used. This information helps to build a case for internal ROI and client testimonials

The competitive edge for your business

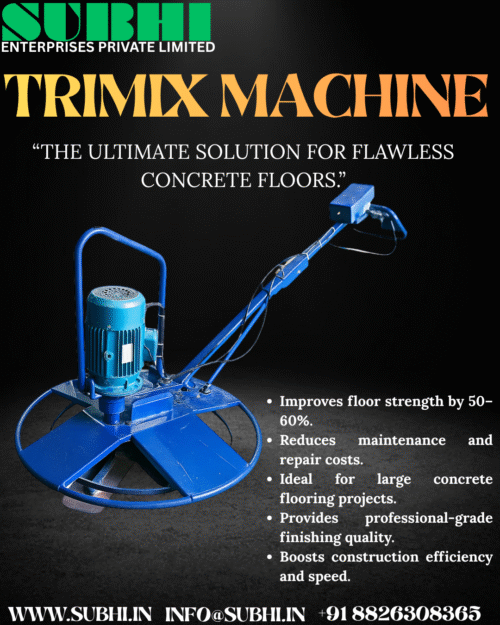

An example can be with your business, “Subhi Enterprises Private Limited.” Selling and marketing construction machines will involve adding the Trimix machine safari to your offerings. This entails:

- A highly beneficial and prominent machine that customers correlate with finish quality.

- A stunning Instagram and LinkedIn post differentiator (you can post pictures before & after showing slabs finished with the Trimix machine—safari).

- A lead-generating conversation piece: Telling a contractor, We supply the Trimix machine – safari, the finishing champion,” opens avenues for credibility.

Customizing the service offer to include servicing, training, and finish reports provides more value.

Last thoughts: Is the Trimix machine safari the right choice for you?

In the simplest terms, yes—if your goal is improved floor finish, rapid turnaround, reduced rework, and dealing with a reputable brand.

But ensure the machine size corresponds to your usual projects, power & logistics on site, operator competence, and maintenance is budgeted for. The Trimix machine—safari is not a “nice-to-have.”

As a construction-machinery business, we do not value machines but outcomes. The Trimix machine – safari helps you achieve faster handovers and smoother slabs with fewer callbacks. This machine becomes an invaluable tool when finishing quality helps you stand out in the market.