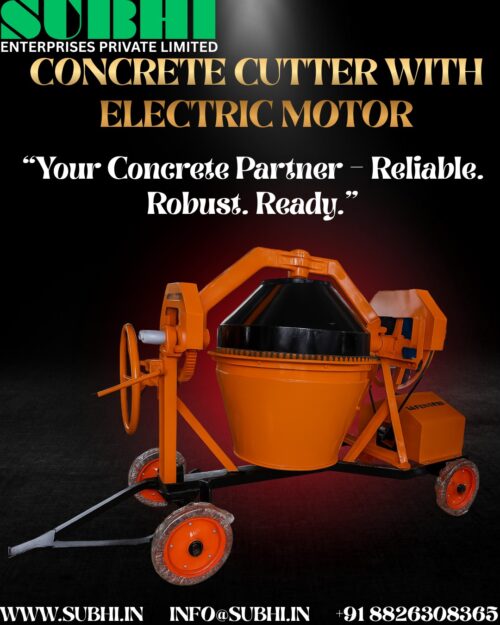

In the ever-changing construction sector, the progress, success, and prompt completion of projects hinge on efficiency, consistency, and dependability. At every construction site, a concrete half-bag mixer (ELECTRIC) is deployed.

This machine is compact but robust, as it lessens the human effort needed to mix concrete components such as cement, sand, and aggregates. Regardless of the scale of your project, be it contracting or construction, or a small independently managed project, the time and labor needed to mingle components is conservatively reduced, and the uniformity of the concrete is ensured.

Concrete Mixer Half-Bag Electric Mixer is durable, energy efficient, and accurately designed to suit the Indian construction environment. Modern construction depicts advanced building projects, but let’s delve deeper into what makes the machine a requisite in the construction environment.

What Is a Concrete Mixer Half-Bag Mixer (ELECTRIC)?

This is a type of concrete mixer machine used for preparing concrete by combining cement, sand, and water. In construction terminology, the machine is of half-bag capacity, which means it can prepare concrete by mixing half a bag of cement, which is roughly 25 kgs.

When comparing traditional mixing techniques to the Concrete Mixer Half-Bag Mixer (ELECTRIC), the latter certainly generates quicker and more uniform results and does so consistently. Unlike diesel or petrol mixers, this electric variant is environmentally friendly. It has the added benefits of being virtually silent and efficient.

Small to medium construction projects such as residential housing, flooring, plastering, and smaller slabs all fall into the scope of this machine. This device maximizes productivity while keeping operational costs to a minimum.

What Are the Benefits of an Electric Concrete Mixer?

The Concrete Mixer Half-Bag Mixer (ELECTRIC) offers the following advantages over its predecessor mixers, which were combustion engine-powered:

- Cost and Energy Savings: Lower fuel cost and pollution because of running on electricity.

- Quiet: High noise levels typical of construction activities are no longer an issue.

- Minimal Maintenance: Lower costs due to the lack of an internal combustion engine.

- Eco-friendly: Emission of absolutely zero noxious gases takes place.

Key Features of Concrete Mixer Half-Bag Mixer (Electric)

For dependable concrete mixing, the Concrete Mixer Half-Bag Mixer (Electric) from Subhi Enterprises has the admirable attributes outlined below:

Heavy-Duty Drum Construction:

For strength and increased wear resistance, the drum is constructed using thick and quality steel.

High-Performance Electric Motor:

For consistent performance, the drum is equipped with a powerful single-phase or three-phase electric motor (1.5–3 HP).

Efficient Mixing Blades:

Scientifically engineered blades provide complete mixing of cement, sand, and aggregates.

Smooth Drum Rotation:

For a stable and vibration-free operation, the drum is equipped with a gear-driven mechanism.

Compact and Portable Design:

Due to a balanced frame and sturdy wheels, the product is portable and easy to move at construction sites.

Easy Maintenance:

Access to the interior parts is simplified to allow easy cleaning and maintenance of the structure.

Technical Specifications (Typical Model)

| Parameter | Specification |

|---|---|

| Mixer Type | Concrete Mixer Half-Bag Mixer (ELECTRIC) |

| Capacity | Half Bag (25 kg cement per batch) |

| Power | 1.5 HP – 3 HP Electric Motor |

| Drum Speed | 20–25 RPM |

| Drum Material | Heavy-Duty MS Steel |

| Operation | Manual Loading/Discharge |

| Power Supply | 220V / 415V |

| Mixing Time | 3–4 Minutes per Batch |

| Mobility | 2 or 3 Wheels (Portable Design) |

At Subhi Enterprises Pvt. Ltd., all our machines are built to these high standards, ensuring long life and reliability on every site.

Applications of Concrete Mixer Half-Bag Mixer (ELECTRIC)

This machine is extremely versatile and finds applications in almost every type of construction project, including

- Residential Building Construction

- Slab Casting and Flooring Works

- Plastering and Finishing Jobs

- Roadside Repair and Patching

- Boundary Wall and Tank Construction

- Small Commercial or Industrial Projects

Its compact size and electric operation make it perfect for both urban and rural use.

Benefits of Using a Concrete Mixer Half-Bag Mixer (ELECTRIC)

Uniform Mixing Quality:

Delivers consistent, homogenous concrete mix every time.

Faster Project Completion:

Mixes concrete quickly, helping contractors meet deadlines.

Reduced Labor Dependency:

Eliminates manual mixing, saving workforce and cost.

Long-Term Savings:

Electric operation reduces operational costs compared to fuel-based mixers.

Easy to Transport:

Moving with the equipment is easily manageable thanks to the compact size.

Eco-Conscious Operation:

No smoke, fuel, or noise—perfect for environmentally sustainable building.

Comparison: Electric vs Engine Half-Bag Mixers

| Feature | Electric Mixer | Engine Mixer |

|---|---|---|

| Power Source | Electricity | Petrol / Diesel |

| Running Cost | Low | High |

| Noise Level | Silent Operation | Noisy |

| Maintenance | Minimal | Regular Servicing Required |

| Eco-Friendly | Yes | No |

| Performance | Consistent | Slightly Variable (depends on fuel quality) |

The most viable option economically and in terms of efficiency is the Concrete Mixer Half-Bag Mixer (ELECTRIC) if electricity is readily accessible in your work area.

How the Concrete Mixer Half-Bag Mixer (ELECTRIC) Improves Productivity

Using electricity to operate the Concrete Mixer Half-Bag Mixer (ELECTRIC) boosts construction site efficiency in a number of ways:

The time and material that would be wasted during manual mixing is considerably higher.

The uniformity achieved in every batch removes the likelihood of wastage.

The increase in work orders during electro-mechanical mixing results in a net positive for the construction site.

For construction site supervisors, the increased work order during electro-mechanical mixing is a game changer, allowing for less time to be wasted.

Maintenance Tips for Concrete Mixer Half-Bag Mixer (ELECTRIC)

These simple steps will save you a great deal of time and ensure that the equipment continues to work for years to come:

Clean the Drum After Each Use:

Hardened concrete that sticks to the blades can cause a lot of issues.

Lubricate Bearings Regularly:

This will keep the parts rotating and smooth while also preventing certain parts from wearing down.

Check Electrical Connections:

Ensure that the wiring and grounding are safe and secure.

Inspect Blades and Drum:

If the blades and drum are worn or damaged, replace them to keep the quality of mixing.

Store Safely:

When out of use, keep the equipment covered and stored to avoid the rain, dust, and direct sunlight.

These practices will prolong the life of your machine and maintain optimum performance.

Why Buy from Subhi Enterprises Pvt. Ltd.?

When purchasing a Concrete Mixer Half-Bag Mixer (ELECTRIC) from Subhi Enterprises Pvt. Ltd., you buy more than a machine. You buy quality, assurance, and service that is going to be with you.

Here is why we are trusted by contractors all across India:

Premium Quality: Made with heavy-duty steel, we maintain the highest standards of durability for the equipment.

Affordable Pricing: We guarantee the best and most competitive pricing for every contractor.

After-Sales Support: Our customer care and service team are always ready to respond.

Genuine Spare Parts: We provide genuine and prompt spare parts for all models.

Fast Delivery Across India: We provide prompt delivery right to your doorstep.

Benefits to Our Customers

Contractors and builders using our Concrete Mixer Half-Bag Mixer (ELECTRIC) have reported:

- Improvement of 25 to 30% in the speed of projects.

- Savings in cost due to reduced cement waste.

- Concrete quality has improved, which results in stronger structures.

- Engine models have higher maintenance costs.

This machine streamlines construction each day by enhancing productivity, reducing costs, and providing efficient, trouble-free operations.

Operating Electric Concrete Mixers Safely

As with performance, safety is essential. Here are safety best practices:

- Utilize a properly grounded electrical outlet.

- Keep the mixer positioned on a flat, stable surface.

- Do not overload the mixer; keep it under half-bag capacity.

- Switch off the mixer before cleaning or attending to maintenance.

- Wear no loose garments or have any loose tools close to the moving parts.

- The above practices assure safe operation with no accidents.

Electric Mixers And The Future Of Construction

Electric equipment, including the Half-Bag Electric Concrete Mixer, is the standard for the future with the construction industry’s adoption of energy-efficient and eco-friendly practices.

Its quiet operation, low costs, and reliable performance are perfect for contemporary urban projects, where balancing productivity with eco-consciousness is essential.

The evolution of motor technologies and varied construction materials ensures these machines increase performance and enhance efficiency, reducing the amount of work builders need to do.

Conclusion

The Half-Bag Electric Concrete Mixer is much more than a construction tool. It is a statement of sustainability, and it is an appeal to efficiency and quality. It is the perfect choice for contractors who seek speed without compromising accuracy.

At Subhi Enterprises Pvt. Ltd., we prioritize delivering electric mixers that excel in every form. Each electric mixer is rigorously strength tested and precision designed to perform and withstand job sites. We aim to support builders throughout India with dependable construction equipment that meets their every need.