Considerations of strength and durability of constructions go hand in hand with precision. Removing air pockets and voids after concrete has been poured is one of the crucial tasks. Needle Vibrators help with this. Concrete compaction is necessary for the protection of the structure as well as its longevity, and Needle Vibrators help with this.

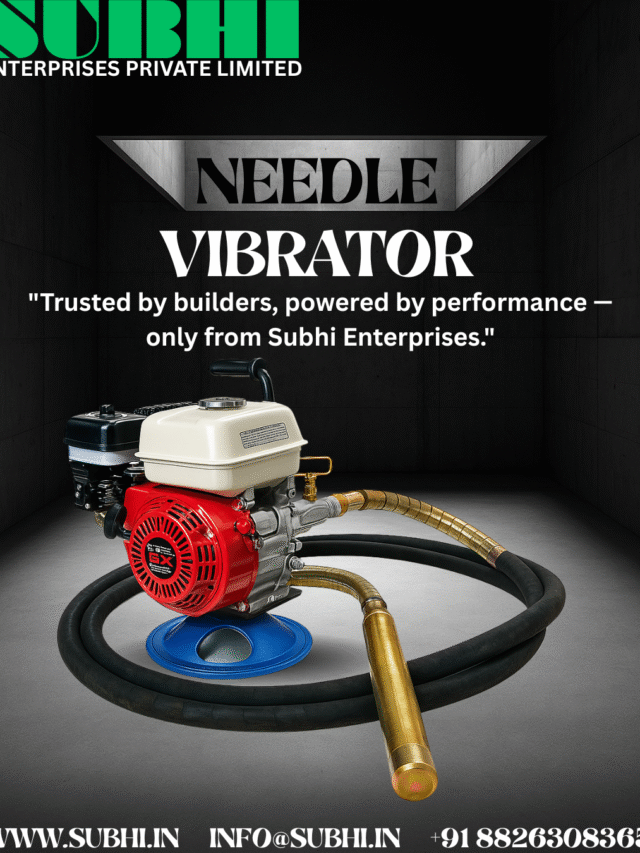

Most advanced Needle Vibrators designed for performance, efficiency, and quality for builders, contractors, and engineers at every pour is the aim of Subhi Enterprises. The type of Needle Vibrators that you use will determine the quality of concrete work for residential concrete slabs, commercial structures, bridges, and roads.

Also known as Concrete Vibrators, Needle Vibrators are mechanical devices designed to remove excess water and voids in the concrete that has been newly poured. To most of the energizing of the concrete, a vibrating needle or poker is attached to a flexible tube connected to a motor. As the air is removed, the concrete particles are liberated and closely bonded, with an overall increase in the density and strength of the structure.

Needle Vibrators improve the quality of your concrete by removing air pockets, which, when trapped, can cause the concrete to become weak with time. This makes the concrete solid, crack-resistant, and durable.

Importance of Needle Vibrators in Construction

Concrete can appear solid and strong, but some weak concrete and the packed voids can remain hidden. Needle Vibrators provide:

Optimized Compaction – The mechanical vibrators on the Needle Vibrators evenly pack and consolidate the concrete, thus uniformly distributing the strength across the entire mass.

Greater Concrete Density – Proper concrete filling of the formwork is achieved by removing the air voids through concrete vibrators.

Concrete-Bonding Improvement – Properly compacted concrete strengthens the bond with the steel reinforcement bars.

Decreased Finishing Work – The concrete’s smooth surface reduces the plastering that is needed afterwards.

Upholding Durability – Needle Vibrators improve concrete consolidation, which enhances durability and resistance to cracking, leaking, and rapid weathering.

Needle Vibrators are now universally relied upon on construction sites across the globe, from small residential constructions to large industrial constructions, to achieve quality concrete.

Different designs and power sources lead to variations in types of Needle Vibrators.

Mechanics of a Needle Vibrator

The system of a Needle Vibrator is simple and effective:

- The vibrating needle is vertically inserted into the newly poured concrete.

- The vibrating needle stirs the concrete mixture.

- Bubbles are formed and trapped within the mixture. Bubbles then float to the top and escape.

- The cement, sand, and aggregate ingredients within the mixture are loosened and then tightly packed.

- The system is repeated, and the needle is moved to ensure all surfaces are uniformly compacted.

As a result, the concrete retains a solid structure, becomes durable, is free of voids, and can withstand extreme conditions and pressure.

These are the top reasons builders and contractors have confidence that Needle Vibrators will produce quality concrete:

- Increased Strength of the Structure

Proper and complete compacting of concrete will create a solid structure, thus the concrete will have a higher cohesive strength and will result in fewer cracks.

- Increased Durability of the Concrete

The concrete that Needle Vibrators have compacted is free of voids; thus, it will withstand the pressure of moving and shifting heavy loads, and vibrating without weakening.

- Superior Finish

Needle Vibrators will compact the surface to be smooth and uniformly compact, thus less surface refinishing will be required.

- Preventing Honeycombing

“Cone Honeycombing” refers to the defects, consisting of gaps, cavities, and voids, as well as various forming imperfections, that concrete creates as it sets. The creation of defects, cavities, and voids can be avoided using Needle Vibrators.

- Reducing Labor and Time

Needle Vibrators enhance the cohesion and voids elimination within the concrete, drastically reducing the time and the number of people required to complete the task.

- Long-Term Savings

Although Needle Vibrators are expensive to acquire, the time and material savings within the construction process, along with the elimination of material wastage, the efficiency of the Needle Vibrator, which contributes to the durability of the structure relative to the cost of construction, saving money in the long run.

Use of Needle Vibrators

Needle Vibrators have multiple applications in construction.

- Concrete slabs and floors,

- Columns and beams,

- Bridges and flyovers,

- Foundations and footings,

- Pavements and precast components,

- Retaining walls and tanks.

Needle Vibrators are fundamental in producing high-quality concrete finishes, whether for residential, commercial, or infrastructural construction.

Needle Vibrator Maintenance

To maintain efficiency and extend the life of your Needle Vibrators, regular maintenance is required. The following maintenance tasks are necessary for each Needle Vibrator.

Cleaning After Each Use:

At the end of each operation, concrete remnants must be cleared from the needle and hose, and the rest of the concrete machine.

Check the condition of cables and hoses.

Examples of hazardous conditions involving cracking and wear that should be looked for include:

Moving parts:

Apply oil or grease where necessary on moving parts to reduce friction that may cause overheating.

Inspect Connection Points:

When using electrically-operated Needle Vibrators, the connections shall be safe and intact with cables and switches.

Store Properly:

Store the vibrator in a clean, dry, dust-free, and moisture-free area.

Your Needle Vibrators will provide years of consistent reliability and performance as long as you follow these few easy tips.

Needle Vibrators Safety Tips

Needle Vibrators are safe and easy to operate; however, the safety tips outlined must be adhered to.

- Always wear all issued safety gear (gloves, boots, helmet, etc.).

- Check all electrical connections before operation.

- Flexible shafts must not be twisted or bent during operation.

- When working with a petrol or diesel variant, do not operate in the vicinity of combustible materials.

- Always disconnect power before cleaning or servicing the machine.

- Safety is the primary instance of machine and worker protection.

Choosing the Right Needle Vibrator

Choosing the correct Needle Vibrators is determined by the project size and the type of concrete. Below is a short guide for you:

Needle Vibrator Selection Guide

| Project Type | Recommended Vibrator Type | Needle Diameter |

|---|---|---|

| Small Construction (Columns, Beams) | Electric Needle Vibrator | 25mm – 35mm |

| Medium Sites (Floors, Slabs) | Petrol Needle Vibrator | 35mm – 45mm |

| Large Infrastructure (Bridges, Foundations) | High Frequency Needle Vibrator | 50mm – 60mm |

At Subhi Enterprises, we offer a range of Needle Vibrators to cater to various site conditions to achieve the primary goal of maximum compaction with minimal effort.

Why choose Subhi Enterprises ?

The reputation of Subhi Enterprises for quality construction machinery, Needle Vibrators, matches the trust we have earned as a manufacturer for all construction machinery. We provide:

- Most optimal construction equipment for your business

- Motors for different frequency vibrations

- Flexible durable shafts

- Simpler equipment for Movement and Maintenance

- Lower cost

Dependable construction equipment to achieve the best productivity and quality of work. We aim to offer you adequate, lower-cost construction solutions.

Quality construction, productivity, and construction solutions of reliable construction working and productivity.

Trust in Customer Support and Service

We believe in trust-building for a solution-oriented approach. Subhi Enterprises gives every client technical support and professional support for the equipment they provide. Once equipment is bought, the customer is provided a warranty, guidance for use, instructional materials, and operation assistance.

Future Use

We acknowledge that the technology used in Needle Vibrators is advancing. We focus on the design and productivity of automated, lightweight, and energy-efficient Needle Vibrators. We are passionate about innovative construction machinery.

As anticipated, future models will include functions such as auto-adjusting vibration control and remote accessibility.

We stand by the value of responsible and sustainable construction and will provide the necessary resources to almost every construction site globally.

Durability of the completed concrete structure starts with proper compaction during the initial construction stages. In order to achieve the compaction that will provide the enduring durability and structural integrity to the completed structure, the construction works must make use of concrete vibrators during the compaction process. Concrete vibrators are necessary equipment regardless of the scale of the project, whether it is a small residential home or larger commercial structures. For such projects, needle vibrators are the proper equipment.