The “skeleton” of a concrete structure comprises steel bars and stirrups that act to bind together the concrete. They are the essential components used to construct columns, beams, piles, and foundations. A laborious and painstaking construction worker creates rebar rings. Not only does it take construction a long time in the manual process, but it also causes rings to be produced in other manners. The rebar ring making machine does not just correct these issues. It demonstrates how much effort and time construction requires. We at Subhi establish trust and work on building and precision and integrated systems. We concur that the construction sector requires machines and systems that incorporate trust and effectiveness in every aspect of their work. To satisfy that requirement, we establish the role of integrated systems in construction as the pillar of sophisticated systems. These systems are founded on trust within special value systems.

What Is Rebar Ring Making Machine, and Why Is It Important?

What are stirrups and rebar rings?

In reinforced concrete construction, vertical bars (longitudinal reinforcement) are tied together with closed steel loops. These are referred to as stirrups or rings. They restrain the vertical bars, resist shear, and prevent buckling of the concrete.

- You may observe the circular and square rings on vertical bars in columns and along the beam length stirrups in concrete buildings that are reinforced.

- The placement, size, and form of the rings and stirrups influence not just the overall safety of the structure, but also how well it functions and sounds.

- Issues You Phase When You Are Make Rings Manually

- The easy bending bars and small project rollers are at fault for not providing good output, and that has a whole lot of issues.

- The issue you first face is inconsistent output. In rings, shape tolerances and diameter tolerances are quite different from what is planned.

- The sluggish rate of hand processes and the restrictions on the number of products made in a day result in low output.

- The heavy control and supervision costs, and the heavy capital to employ skilled labor, may be a major issue. Rings that are broken due to mere bending, computation errors, or poor process control might generate a lot of scrap.

- For Subhi’s rebar ring making machines

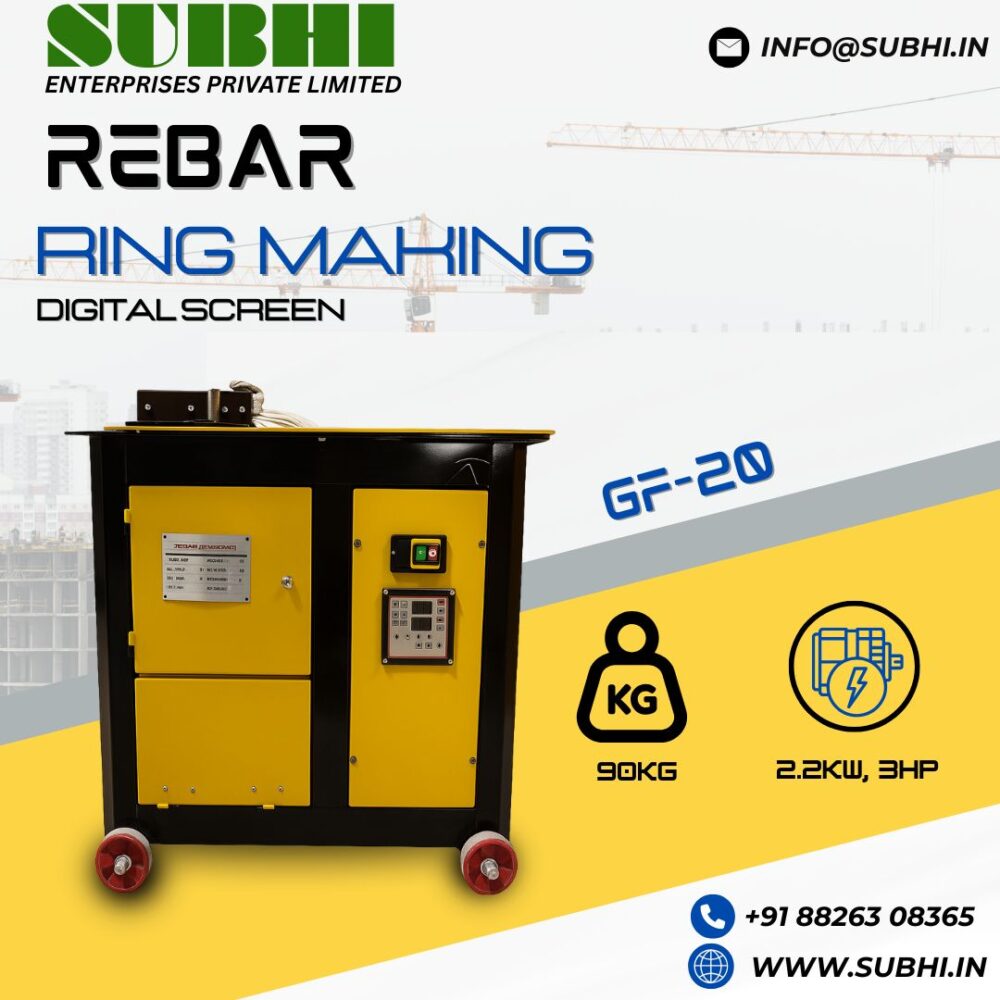

In North India, Subhi Enterprises (www.subhi.in) is renowned as one of the finest destinations for dependable, precise, and user-friendly construction machinery. GF20 Digital Rebar Ring Making Machine (single/three phase) is among their flagship products. We have a comprehensive product range that includes plain functional design rings, bars as guides, and simple guides with circles or limiters.

Now, let’s talk about what sets Subhi Enterprises’ construction machines apart from the rest.

Basic information about the GF20 Series for Subhi, including specs and tech details.

You can get the specifications for Subhi’s digital version GF20 at subhi.in.

- Value, range, and parameters specifications

- Model: GF20D (version with a digital screen)

- Diameter of the bending bar: 4 mm to 16 mm

- Power of the motor: 2.2kW/3HP

- 415V/3 Phase (for the digital version) subhi.in

- Bending Speed: 1,440 RPM (speed of input motor) subhi.in,2 subhi.in,2

- About The rebar ring making machine weighs 90 kg, placing it in the portable category.

There are two paddles: 2 nos. subhi.in,1

In addition to the GF20, Subhi makes a full range of Bar Ring Making Machines for standard stirrup sizes that work with TMT bars from 6 mm to 16 mm. subhi.in

As for why it can be scaled up, it’s because it can be compared to industrial machines with better specs.

The GHM of rebar ring making machine is capable of bending bars from 16 to 32 mm diameter, circles with diameters ranging from 800 to 2200 mm, and circles with bending speeds of 25,000 mm/min.

ghm machinery.com

The larger GF26D model bends 4 to 20 mm thick bars and comes equipped with a 3kw motor.

sonavibrators.com

The Chinese SC-type machines have 8–16 mm bars, 7.5 kW power, and automatic hydraulic cutting. zzyongchuang68.en.made-in-china.com

The model Smit OWH-32 is able to cut 16 to 32 mm thick bars at 12 RPM for heavy-duty jobs.

The following comparisons highlight that Subhi’s GF20 is suitable for small and less sophisticated structural work. Their Enterprise partners (and theirs) are also capable of taking larger machines on request. Individuals regard Subhi as the GF20 Digital.

Subhi’s first-class choice model is the Digital GF20.

Novmachan indicates Subhi GF 20 “Digital” has begun “to digitally electronically record and display arch bending programme heights” in “real time.” and monitor performances for the operator when the arch is bent to the machine settings and nearing the pre-set heights the operator can access. It stores and “customises” the bending programme settings for “repeated arch production.” The Subhi GF 20 “Digital” is the first Subhi model.

Subhi GF 20 “Digital” has “started to digitally electronically record and display arch ‘bending programme heights’ in ‘real time’. and record performances for the operator when the arch is bent as per the machine settings and is nearing the pre-set heights the operator can achieve. It also stores and customizes the bending programme settings for repeated arch manufacture.”. The “Digital” model is light and portable. The first “Digital” model is the Subhi GF 20 Digital, which is identical to the GF 20.

The Subhi GF 20 “Digital” range, Novmachan, is able to “digitally electronically” take “in real-time arch” bending programme heights and “flowing recorded performances” for the operator “when arch is bent according to machine setting and is approaching the operator-reached pre-set heights.” It can also “store custom” “bending programme settings” for “repeated arch production.”

Full Range of Bar Diameters

The majority of the usual sizes of building rebar employed in columns, beams, and slabs of residential or mid-rise construction are between 4 mm and 16 mm.

Fast speed and efficiency

1,440 RPM is the fast bending cycle speed, so the machine is able to perform a great deal of work in a short amount of time. This is crucial on busy construction sites.

Parts and Maintenance

The basic core mechanical design is simple and easy to maintain and safe. Some of the key components of the machine design also reduce downtime when they must be replaced.

Safety and Dependability

Subhi equipment is designed for durability with robust MS and steel frames, as well as conditions-ready parts and guards. It is far more risky to the operator’s health when they manually control bending items, and hand bending is safer than digital control. This is due to the fact that the operator doesn’t need to relocate the machine as frequently.

The Steps That the Machines Follow

The workflow needs for it to be evident that it needs to be automated.

Loading Materials

An entry guide allows the feeder to ingest a steel bar, either straight or in coil form, provided it is between 16 and 4 mm in diameter. The jaws of the machine grip the bar once ingested.

Input of Parameters

The operator has to input the inner diameter, rings number, and any offset in spacing that they desire while the process is ongoing. Depending on the input parameters, the control logic determines the length of arc to be bent.

Bending and turning

The motor rotates the paddles (or bending rolls) to bend the bar to the desired bending radius.

The bending paddles move on their own to keep the bar’s shape and contour as it bends.

Completion and Cut (if there is one)

The system keeps track of the bar’s position on its own. When it reaches the stop position that has been set up, the cutter that is built into the system will stop and cut the bar.

The formed ring can be ejected automatically or by hand.

Again

The sequence operates automatically depending on the number programmed.

The purpose of this automatic update is to reduce the involvement of human beings and maintain the update going at a continuous, contemporary pace.

- Benefits and Value Proposition

- Employing Subhi’s GF20 Digital will benefit operations because

Quality and Consistency

- There is a need for the design that all the stirrups and rings are the same radius and size.

Speed and throughput

- You can produce more rings per day, which accelerates the construction process.

Savings on costs

- There are savings in labour, rework, and material. Skilled labour will be able to operate machines rather than hand-bending the rings.

Being able to change

- You can adjust the size and shape of the rings for fit on the beam, column, or slab.

Easy to carry

- The equipment can be taken to the site rather than having centralised stores, reducing the amount of material movement.

Capacity to increase

- If required, smaller building projects can be handled by the GF20 alone. For larger construction projects, if heavier bars are required, Subhi or one of the partner suppliers can arrange heavier machines.

Competitive edge

Clients, consultants, and sub-contractors will have faith in you if you are able to provide quality, precisely processed reinforcement in record time.

When GF20 performs at its best

Subhi’s GF20 rebar ring making machine is a break-through for such projects:

Mid-rise construction sites of homes and businesses.

Small in medium-sized precast concrete plants. Reinforcement workshops in open houses for local contractors. Rebar diameter infra projects that are not excessively large (≤16 mm). When it comes in coil or bar form, it is fabricated on site. In case the project is larger than 20 mm, the GF20 will be insufficient. Heavies such as the GF26D or SC-series would be ideal for those. How to Choose the Right rebar ring making machine

The most crucial things to consider when purchasing rebar ring making machines are:

- 1.Capacity for Bar Diameter

- Consider the various diameters that the machine can accommodate, and ensure to include a rebar diameter that is more difficult for the machine to handle.

- Torque and power of the motor

- To ensure that the load doesn’t stall, power must be sufficient. Power usage increases when bars become thicker or when movement cycles are faster, and so you require more horsepower.

- Control and Automation

- The inclusion of features such as fully automated on/off controls, programmable memory, digital control, and automated cut-off control makes a system worth more.

- Speed/RPM

- Optimised gearing lets the input RPM go up, which speeds up the cycle time.

- Quality of the Frame and Build

- Heavy-duty machine construction, solid welding, and precise machining make machines that last longer.

- Weight vs. Portability

- The weight of the machine makes it less portable, but less weight makes it more rigid. Pick what you need for your job site.

- Spare parts and assistance

- You will be able to obtain spare parts immediately with a local supplier like Subhi, without having to wait weeks.

- Return on Investment vs. Cost

- You ought to be able to see a clear picture of the ROI by viewing the number of rings produced each day and the contribution of the machine in terms of labour and rework value. In most instances, it is possible to achieve this quickly.

- Subhi’s GF20 digital controls are now popular and reliable in the industry due to their relatively affordable prices and well-done after-sales service. They are now used by construction companies all around the nation.

Subhi’s GF20 Digital Rebar Ring Making Machine might make reinforcement work better in an easy manner.

The machine can produce rings between 4 and 16 mm in diameter.

The digital system of the machine and simple features allow operators to select the number of rings and the ring size that they wish to produce. The weight of the machine is 90 kg, which makes it simple to transfer. GF20 is ideal for workshops and construction sites since it produces things with consistent quality. Recommended confidently to construction crews because the customer support within this industry is prompt and responsive.

Best Operation and Maintenance

- To achieve the most work from and the highest quality out of your rebar ring making machine, you must do the following:

- Establish and maintain a routine schedule for greasing and lubricating all rotating and pivoting points, as well as the gear assemblies.

- Perform all the regular calibrations and adjustments to the bending radius and digital system.

- Ensure that the guides and paddles are aligned and configured in a symmetrical manner.

- Ensure that the input bars are not damaged or broken, and are straight.

- In order to assist in keeping the machine safe, provide it with a dust cover or sheet metal guard.

- Put back the dust and dirt into the machine so that it will function optimally.

- Operator maintenance.

- Replace old small components such as paddles, cutters, belts, etc. This will enable you to establish the proper norms for routine maintenance.

- Subhi’s service team is in a geologically significant region of Northern India, making it convenient for them to assist you with your service, maintenance, and parts inquiries.

- Future Upgrades and Predictions

- Improvements in the rebar fabrication industry have been numerous and are not limited to the following:

- Development of robots and CNC machines capable of bending and shaping rebar into intricate and irregular forms, cages, and frames.

- Utilization of Building Information Modelling (BIM) and digital workflows to automatically include stirrup schedules in plans.

- The application of adaptive algorithms for bending rebar which prevents spring-back with a high amount of force.

- The capability to sense machines at a distance, know when they are about to need maintenance, and interconnect them to the Internet of Things (IoT).

- The automated and sophisticated control of new machine systems that can accommodate rebar with diameters of 20 to 40 mm.

- Subhi’s position in the marketplace provides for client-centered, best-fit partnerships and the designed implementation of these changes.

In conclusion

Rebar stirrups and rings can appear indistinguishable and “boring,” but getting these components delivered is crucial to the building’s structural stability. That is why Subhi Enterprises’ machines, such as the GF20 Digital, are engineered by us for the small-to-mid rebar size range. We would like to achieve the optimal balance between performance, price, and user-friendliness.

With growth in business as structural fabricators, contractors, and construction firms, it is impossible to do without an integrated ring-making machine. It has become a necessity rather than a luxury.Only deal with machine suppliers such as Subhi who will assist you with your machines, work with you, and be reliable.

I can have this piece ready for your blog by inserting headings, images, and sub-sections, or I can optimize it for some SEO keywords. Would you like me to send you that version?