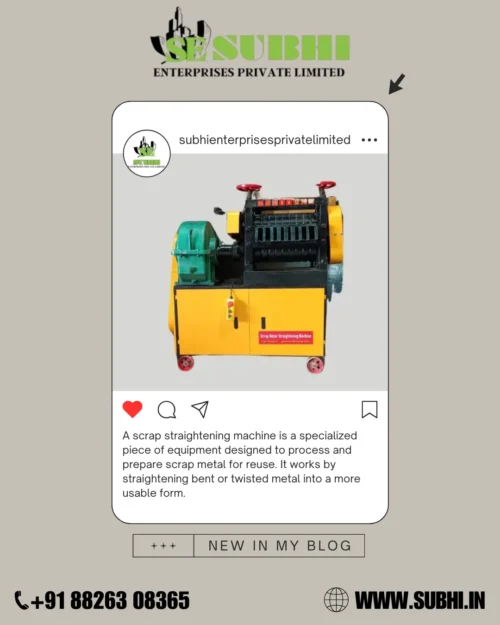

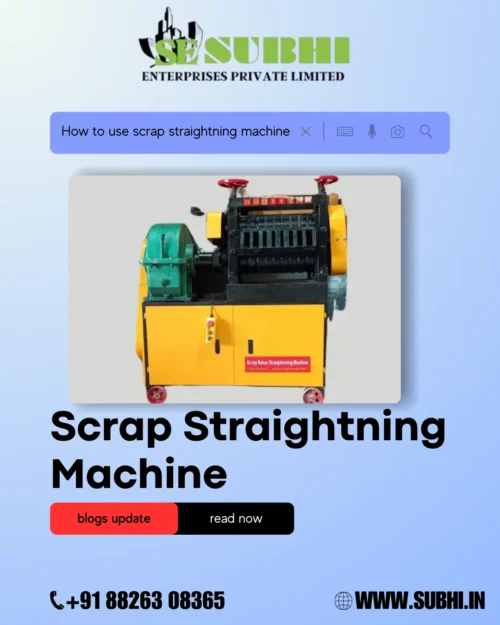

Scrap Straightening Machines

There are many types of steel bars that can be straightened with the help of scrap bar straightening machines such as reinforcing bars (rebar), scrap steel and other structural materials. The main purpose of these machines is to make crooked or deformed bars usable again so that they can be processed further or directly used in construction projects.

How They Work

A typical scrape bar straightening machine straightens bent bars using a mechanical approach. First, bent bars are fed into the machine where several rollers or mechanical parts apply pressure to the bars to bend them back into shape. Moreover, the mode of operation is quick and efficient as it does not damage the surface of the bars and ensures no scratches are left.

The rest of the parameters of the Scrap Straightening Machines are the following:

1. Increased Output

These are designed to deliver better productivity and speed. In a short timeframe, these machines can process large volumes of scrap metals which is convenient for buildings under construction and for recycling centers.

2. Adaptability

These machines are built to accommodate various sizes and types of steel bars ranging from small Rebars to larger structural steels. This enables the user to easily shift from one project to another with the different materials available.

3. Surface Protection

A number of machines are made for the purpose of straightening bars without scratching or damaging the surface which is critical in preserving the quality of the material, in particular when it will be put to use in a visible application.

4. Easy To Use

The majority of scrap straightening machines is accompanied by intuitive automatically controlled interfaces which makes it easy to operate by people with an assortment of skills. This will decrease the learning curve while increasing productivity.

5. Reliability And Strength

These machines are built from strong materials with defined engineering which helps the machine withstand the heavy workload that is usually found in industries. The machines bring out efficiency which allows for steady output performance over time.

Perks of Bar Scrap Straightening Machines:

1. Economic Advantage

Companies can maximize material costs as the scrap metal can be reused by melting and reshaping it. This is especially advantageous for sectors that rely heavily on raw materials.

2. Environmental

Sustainable straightening machines encourage eco-friendly practices in the building and metal sector by minimizing waste production and usage of new materials. Improved engineering methods increase the efficiency of business operations, making them more sustainable.

3. Optimized Material Strength

Any infrastructure development program that utilizes recycled components requires strength and toughness to meet certain basic accepted standards.

4. Boosted Work Performance

The machines allow companies to turn more work and in the same time be able to meet the deadlines due to the faster turnaround time.

Use Cases of Scrap Straightening Machines:

Construction: Straightened rebar is required in reinforcing concrete structures in the construction industry. These machines guarantee the rebar used is of great quality and devoid of defects.

Metal Revalorizations: Such devices are utilized in the recycling industry to ready old metal for export or subsequent reprocessing which assist in the effective use of the wastage.

Manufacturing Processes: Straightened bars are amongst the basic requirements of metal product manufacturing companies and Scrap Straightening Machines have proven to be a valuable source of high quality raw material for them. (click)

An Overview of Scrap Straightening Machines

These machines are used to straighten different kinds of steel bars, which include reinforcing bars (rebar), scrap steel, and other steel structures. The purpose of these machines is to make bent or unusable bars into a form that can be processed further or used as is for construction work.

Working Mechanism

To set up a this machine, the first step in operation is to place the bent bars into the machine. Within the machine, there are rollers or other moving parts that grab onto the bar and attempt to straighten it. Most systems are artificially created so that the setup and implementation process can be as swift as possible. Subsequently, the bars are straightened with the least amount of surface damage. (click)

Inefficiency is hardly a problem with modern machines, and these machines are no exception. Recent developments in manufacturing have resulted in machines that can handle enormous amounts of scrap metal in record time, making them very useful for covering construction sites.

Flexibility: The machines are capable of processing all sizes of steel bars ranging from rebar to large structural steel components. This flexibility enables the users to modify the machine for different projects and materials.

Protection of the Surface: Most of the machines are constructed in such a way that they can straighten the bars without leaving marks on them. This is important for the application of the material, especially when its quality is useful for the aesthetics.

Simple to Operate: Most of the controlled and straightening scrap bar machines are user friendly and can be controlled by workers of any skill level. This enhances productivity by reducing the time needed for training.

Strong and Trustworthy: These machines are made of strong materials and are professionally designed to endure the harsh conditions of frequent usage in industrial settings. Their performance stability over a long period is what makes them trustworthy. (click)

Conclusion

Construction and metalworking sectors have come to appreciate the value of scrap straightening machines because of their efficient and versatile solutions for the recycling and reuse of steel materials. Because of their particular characteristic of easily improving the material composition, they are considered very important in the current industrial market. Given that there is a growing concern for the environment as well as a concern for decreasing expenses, these machines will definitely be highly sought after.

Businesses can significantly lower their expenses and increase their operational productivity. It is an incremental step towards a more sustainable world. A dedicated scrap straightening machine for scrap bars is an extremely beneficial addition to any manufacturer, constructor or even recycler, because it is practically guaranteed to provide positive returns on investment. In-Depth Overview On Scrap Straightening Machines

In every metalworking and construction business, there is a continual need to modify and rework already used steel rods and bars which are bent or twisted into different shapes, and this can be efficiently performed by a scrap bar straightening machine. These machines are very important during the recycling phase of scrap metals and can help greatly increase the amount of materials that could otherwise be wasted.

This blog discusses the scope, advantages, and uses of scrap bar straightening machines across different manufacturers and products.