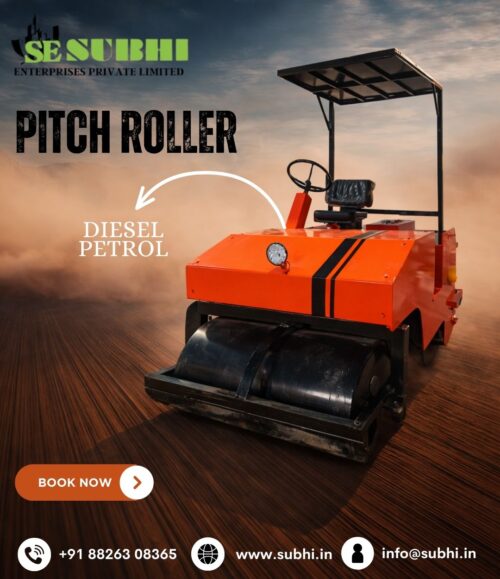

In cricket, the quality of the match pitch is instrumental to the outcome. The level of service of both international and local fields is determined by the pitch preparation, the aim of which is to ensure a fair bounce, an even pace, and safety of the players. Among the various pitch preparation tools, the diesel cricket pitch roller is one of the most reliable, effective, and powerful machines that can assist in pitch preparation.

As the name suggests, a diesel cricket pitch roller is powered by diesel and is designed to assist in the compaction of soil, providing a cricket pitch that is level and firm and a surface that is durable to play on. It is used by cricket ground staff, cricket sport academies, sports authorities, and stadium managers. In this guide, we will explore all the applicable aspects of diesel cricket pitch rollers, including the features and maintenance, benefits and applications, and how to select the most suitable diesel pitch roller for your needs.

What is a Diesel Cricket Pitch Roller?

A diesel pitch roller is a large industrial-sized roller that compacts and levels cricket pitches using a diesel engine. Compared to manual and electric rollers, diesel rollers provide a greater amount of torque and consistent performance. Therefore, these diesel rollers are used more heavily for large grounds/professional pitches.

The primary function of a diesel cricket pitch roller is to compress an even layer of soil, thus improving the soil structure to be more homogeneous with fewer voids, and to create a greater surface. Well-maintained pitches have a greater top layer, which creates a more desirable surface for a bounce that is predictable and a pitch that is more durable, thus resulting in improved performance throughout longer matches and tournaments.

Why Pitch Rolling is Vital in Cricket

Flattening the surface of a pitch is only a small part of the art that is pitch rolling. The way the game is played is dependent on pitch rolling.

Good rolling provides:

- Consistent ball bounce

- Balanced pace and swing

- Reduced risk of injuries

- Longer pitch life

- Improved drainage and stability

diesel pitch roller provide compacting of a level that is professional and difficult to match with smaller/lighter machines.

How a Diesel Cricket Pitch Roller Works

The working principle of a diesel pitch roller is simple.

The diesel engine provides power, which drives the roller for movement and systems, which in turn drives the roller drum. The heavy roller drum, which is added as an external piece to the roller system, provides downward pressure on the pitch surface.

- Soil layers are compacted uniformly over multiple passes.

- Soil moisture combines particles, resulting in a solid surface.

Because a diesel pitch roller provides constant flow, it applies even pressure while rolling, ensuring that pitch quality stays consistent.

Features of a Diesel Cricket Pitch Roller

A diesel pitch roller of exceptional quality considers operator comfort, durability, and performance. Common design attributes are:

- High-Performance Diesel Engine

Diesel engines have been reputed to be very fuel efficient and have high torque. This suggests that diesel cricket pitch rollers are ideal for extensive workloads with minimal refueling.

- High Mass Roller Drum

The mass of the drum is a significant determinant of the degree of soil compaction. A drum with greater mass will yield a higher degree of compaction.

- Heavy-Duty Steel Construction

A diesel pitch roller can endure difficult ground conditions and rough use over an extended period.

- Seamless Operation

With the pitch being narrow, precise and even movements require advanced steering and driving control systems.

- Minimal Servicing

Compared to petrol engines, diesel engines require service less frequently, as they are more durable.

Using A Diesel Cricket Pitch Roller

Compared to other rollers, diesel cricket pitch rollers have more advantages.

- Unmatched Compaction Ability

The heavyweight and torque of a diesel cricket pitch roller offer deeper and more effective compaction, leading to a harder pitch.

- Perfect for Large Facilities

Rollers that are powered by diesel are great for large venues such as stadiums, cricket academies, and multi-pitch facilities where time is of the essence

- Long-Term Cost Savings

While the initial purchase may cost more, diesel pitch roller are more cost-effective over time because of their fuel efficiency and long-lasting construction.

- Reliable Performance

Unlike electric or manual rollers, diesel-powered rollers provide uniform speed and pressure.

- Top-Tier Pitch Quality

diesel pitch roller help you reach pitch conditions of the highest international standards.

Choosing a Pitch Roller

Understanding differences between each roller is essential.

| Feature | Diesel Cricket Pitch Roller | Electric Roller | Manual Roller |

|---|---|---|---|

| Power | High | Medium | Low |

| Compaction | Excellent | Good | Limited |

| Coverage Area | Large | Medium | Small |

| Operating Cost | Moderate | Low | Very Low |

| Skill Requirement | Medium | Low | High |

The Uses of Diesel Cricket Pitch Rollers

A diesel cricket pitch roller can be found in numerous cricketing venues, such as

- International and domestic cricket stadiums

- Cricket academies and training centers

- School and college cricket grounds

- Multi-sport complexes

- Private cricket clubs

The diesel cricket pitch roller is the best choice wherever pitch preparation needs to be of the highest quality.

Selecting the Best Diesel Cricket Pitch Roller

There are several key factors to keep in mind when deciding to purchase a diesel pitch roller:

- Roller Weight

Heavier rollers are better for compacting, so choose based on the pitch and soil type.

- Engine Capacity

A strong, reliable diesel engine is important for smooth operation and longevity.

- Drum Width

A drum that is too narrow can limit efficiency.

- Ease of Operation

Choose a model that has comfortable seating, responsive steering, and operational controls.

- After-Sales Support

Select a supplier or manufacturer that has reliable service and readily available spare parts.

Maintenance Tips for Diesel Cricket Pitch Rollers

Consistent operation and longevity are the results of proper maintenance of your diesel pitch roller.

Oil the engine, if needed.

When needed, change the air filter.

- Check the fuel hoses.

- Oil the machine’s joints.

- Store the machine indoors.

A diesel pitch roller has the ability to last many years if taken care of properly.

Diesel Cricket Roller Safety Guidelines

Safety is the first priority when rolling the pitches.

- Always roll the pitches on even surfaces

- Never make sharp turns on soft/damp soil

- Make sure the machine operator is well trained

- Don’t exceed the machine’s weight limit

- Always check the machine for safety before use

These guidelines are to help use the diesel cricket pitch roller effectively.

Diesel Cricket Pitch Roller Environmental Impact

Using newer diesel cricket pitch rollers positively impacts the environment, as they perform better while emitting less pollution.

Why Do Professionals Choose Diesel Cricket Pitch Rollers

Doing test matches, professional cricket grounds will use diesel cricket pitch rollers to be certain they are receiving the reliability and consistency they expect.

Advancements in design and engine technology are making diesel cricket pitch rollers more efficient, quieter, and greener. Increased user-friendliness is achieved through features such as improved vibration control and ergonomic design.

Conclusion

For those who are truly committed to the art of preparing cricket pitches, investing in a diesel cricket pitch roller is worth it. It is the most powerful, most durable, and most efficient, after all. Professional grounds and big cricket facilities will benefit the most. Diesel cricket pitch rollers deliver the most on both pitch safety and compaction and on pitch performance to meet international standards.

Investing in diesel cricket pitch rollers is a sound and smart investment. You will get professional pitches, long-term value, and reliable results.